What are Some Reasons Why You Should Choose WPC Door for Interior

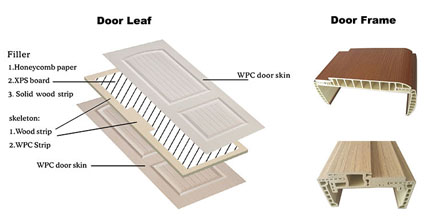

WPC door is made of wood superfine powder particles mixed with polymer resin, manufactured by wood plastic process, with the good performance of both wood and plastic, so that wood plastic door to achieve the real effect of imitation wood, is to replace the traditional wood door green and new products